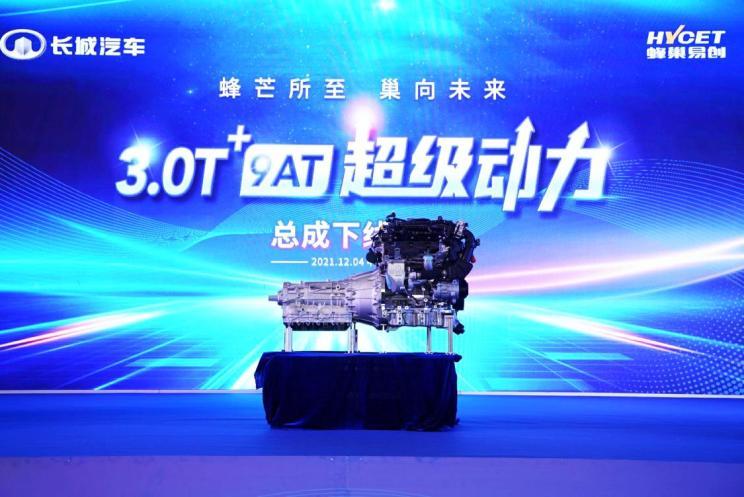

Great Wall Motor (GWM) is the largest SUV manufacturer in China. GWM recently tapped Amsted’s MVT Advanced Metal Forming Processes to help produce the transmission production parts for their new “super powertrain”—an indomitable 3.0T V6+9AT powertrain for TANK, Great Wall’s luxury brand of off-road vehicles.

Amsted produced five clutch carriers for TANK’s all-new automatic transmission, two of which were developed on a GROB T12 machine. That made Amsted the first company in China to use the GROB machine for intermittent forming processes.

To produce GWM’s highly advanced 9AT transmission, we also employed the following technologies:

- Stamping preform

- GROB spline form

- Finish stamping in transfer press (trim-pierce)

- Machining of tight-tolerance features

It’s especially exciting because GROB’s intermittent forming sheet metal allows for the high-efficient production of complex components through shorter cycle times.

Amsted Automotive is ever-evolving.

MVT represents an ongoing collaboration between the metal-forming and joining expertise of our Transform Products unit and our VT Industrial Technology proficiencies in complex tooling manufacturing.

MVT is expanding rapidly in the Chinese automotive market as the country’s escalating needs for next-level powertrain and advanced metal forming precision grow.

In addition to our partnerships in China, MVT will serve the metal forming and tooling needs of the European and Japanese markets as well.

Curious what MVT can do for your powertrains? Let’s talk.